In the world of precision electromechanical systems, synchros and resolvers play a crucial role in measuring angular position, velocity, and direction. These devices are widely used in military, aerospace, industrial automation, and robotics applications, where accuracy and reliability are paramount. While both synchros and resolvers serve similar purposes, they differ significantly in design, functionality, and performance. Understanding these differences is key to selecting the right technology for specific applications.

This article delves deep into the distinctions between synchros and resolvers, exploring their working principles, variations, and applications. It also provides a detailed comparison to help engineers and decision-makers choose the optimal device for their needs.

What Are Synchros and Resolvers?

Synchros

A synchro is a type of rotary transformer that converts angular position into an electrical signal. It consists of a rotor and a stator, with the rotor being mechanically connected to the shaft whose position needs to be measured. The stator is equipped with windings that generate electrical signals proportional to the angular displacement of the rotor.

Synchros are commonly used in applications that require precise angular position data, such as radar systems, ship navigation, and military equipment. Their robustness and ability to operate in harsh environments make them a go-to choice for critical applications.

Key Features of Synchros

Analog operation

High reliability in extreme conditions

Simple construction with fewer components

Used primarily in military and aerospace systems

Resolvers

A resolver is another type of rotary transformer, but unlike synchros, it uses sine and cosine signals to represent angular position. The resolver's rotor has windings that induce voltages in the stator windings, which are proportional to the sine and cosine of the rotor's angular position. These signals can then be processed to compute the exact position or velocity.

Resolvers are highly valued for their precision and are extensively used in industrial automation, robotics, and modern servo motor systems. Their ability to withstand vibration, shock, and temperature extremes makes them highly reliable in demanding environments.

Key Features of Resolvers

Analog operation with sinusoidal signals

High resolution and accuracy

Excellent noise immunity

Widely used in industrial and servo applications

Variations on the Synchro and Resolver Theme

Over time, several variations of synchros and resolvers have been developed to meet specific application requirements. These variations, while rooted in the same basic principles, offer unique features and capabilities.

Brushless Synchros and Resolvers

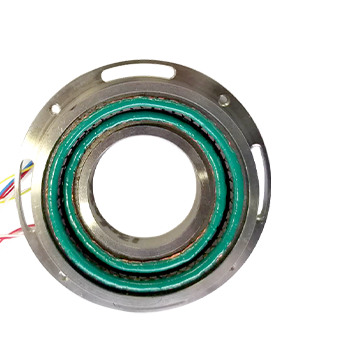

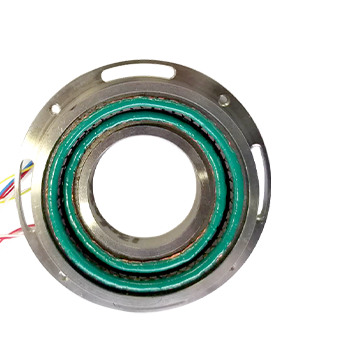

Traditional synchros and resolvers use brushes and slip rings to transfer electrical signals to and from the rotor. However, brushless synchros and resolvers eliminate these components, enhancing durability and reducing maintenance requirements. They achieve this by incorporating rotary transformers or other non-contact methods for signal transmission.

Advantages

Increased lifespan due to the absence of wear-prone brushes

Improved reliability in harsh environments

Reduced maintenance costs

Brushless designs are particularly popular in aerospace and industrial applications where long-term reliability is critical.

Magslips

Magslips are a variation of synchros that use magnetic coupling instead of physical electrical connections. They consist of a primary winding (transmitter) and secondary windings (receiver), and they operate based on mutual inductance. Magslips are simpler in construction and are often used in applications where moderate accuracy is sufficient.

Advantages

Transolvers

Transolvers are hybrid devices that combine features of both synchros and resolvers. They are capable of converting angular position data into electrical signals and vice versa. This bidirectional functionality makes transolvers versatile and useful in systems that require both feedback and control capabilities.

Applications

Slab or Pancake Synchros and Resolvers

Slab or pancake synchros and resolvers are designed to have a flat, compact form factor. Unlike traditional cylindrical devices, these are optimized for applications where space is limited. Their lightweight and low-profile design make them ideal for use in modern aerospace and robotics systems.

Advantages

Multipole or Electrically Geared Synchros and Resolvers

Multipole synchros and resolvers feature additional poles on the rotor and stator, allowing them to achieve higher resolution and accuracy. These devices are often referred to as electrically geared because the extra poles effectively multiply the angular resolution.

Advantages

Enhanced resolution and precision

Suitable for high-accuracy applications

Widely used in advanced robotics and CNC machinery

Comparison Between Synchros and Resolvers

To better understand the differences between synchros and resolvers, let's compare their key characteristics in a tabular format:

| Feature | Synchros | Resolvers |

| Signal Representation | Analog signals proportional to angular position | Sinusoidal (sine and cosine) signals |

| Accuracy | Moderate | High |

| Resolution | Limited | High, especially in multipole designs |

| Noise Immunity | Moderate | Excellent |

| Operating Conditions | Highly reliable in extreme environments | Equally reliable, with added noise resistance |

| Applications | Radar, navigation, military systems | Robotics, servo motors, industrial automation |

| Maintenance | May require brush replacement (in traditional designs) | Minimal (brushless designs available) |

| Signal Processing | Requires simpler processing | Requires more advanced signal processing for sine/cosine signals |

| Cost | Typically lower | Slightly higher due to added complexity |

From the table, it's evident that while both devices offer robustness and reliability, resolvers excel in applications requiring high resolution and noise immunity. Synchros, on the other hand, are better suited for simpler systems where cost and ease of integration are priorities.

Conclusion

Both synchros and resolvers are indispensable in the field of motion control and position sensing. While they share similar principles, their differences in design, accuracy, and application make them suitable for distinct use cases. Synchros are ideal for rugged, cost-sensitive environments, whereas resolvers shine in high-precision, noise-prone scenarios.

As technology evolves, variations like brushless designs, transolvers, and pancake configurations continue to expand the capabilities of these devices. Understanding these nuances is crucial for engineers and system designers looking to optimize performance in their specific applications.

When choosing between a synchro and a resolver, consider factors such as accuracy, environmental conditions, cost, and signal processing requirements. By aligning these considerations with the strengths of each device, you can ensure the best fit for your project.

FAQs

1. What is the primary difference between a synchro and a resolver?

The main difference lies in their signal representation. Synchros produce analog signals proportional to angular position, while resolvers generate sinusoidal signals (sine and cosine) that offer higher resolution and noise immunity.

2. Which is more accurate: a synchro or a resolver?

Resolvers are generally more accurate due to their sinusoidal signal output and higher resolution capabilities.

3. What are brushless resolvers, and why are they important?

Brushless resolvers eliminate wear-prone brushes and slip rings, resulting in increased durability and reduced maintenance. They are widely used in aerospace and industrial applications.

4. Can synchros and resolvers be used interchangeably?

While they serve similar purposes, their differences in accuracy, cost, and signal processing requirements mean they are not always interchangeable. The choice depends on the specific application.

5. What industries use synchros and resolvers?

Synchros are commonly used in military, radar, and navigation systems, while resolvers are prevalent in robotics, industrial automation, and servo motor systems.

6. Are there modern alternatives to synchros and resolvers?

Yes, modern alternatives like digital encoders and other advanced sensors are available. However, synchros and resolvers remain relevant due to their robustness and reliability in extreme environments.

7. What are pancake resolvers?

Pancake resolvers are compact, flat versions of traditional resolvers, designed for applications with limited space, such as aerospace and robotics systems.